Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2021-03-01

The air-jet loom is a new type of loom that uses the high-speed airflow generated by the released compressed air to draw the weft through the loom to complete the weft insertion. It is currently the fastest growing machine type in the Shuttleless Loom.

Air-jet weft insertion uses air as the weft insertion medium to draw the weft yarn by the compressed air jets to generate frictional traction, take the weft yarn through the shed, and achieve the purpose of weft insertion through the jet generated by the air-jet.

Features of jet weft insertion

The characteristics of air-jet weft insertion are high speed, high tension, small shed, and high requirements for raw yarn and semi-finished products.

Air-jet weft insertion is a passive weft insertion method. The tension of the weft yarn is small when flying over the shed, and there is no control. Therefore, it lacks sufficient traction for the weft yarn with high linear density or fancy yarn. At the same time, the warp yarn shedding state has a great influence on the quality of weft insertion, and it is easy to produce fabric defects such as weft shrinkage and weft return.

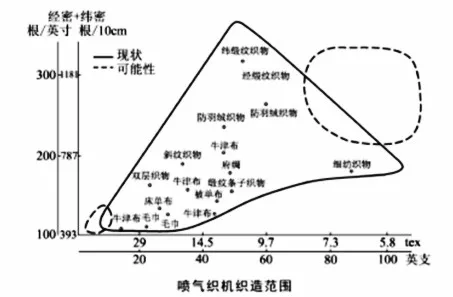

The early air-jet looms had a very small range of adaptation, mainly producing white grey fabrics, with small fabric widths, slow speeds, large fabric limitations, and low fabric quality. However, since the early 1980s, with the development of air-jet looms with special-shaped reeds and relay weft insertion technology, as well as the application of electronic computers, sensors and frequency conversion technology, the speed of the air-jet looms and the automatic monitoring of the loom have been greatly improved. In particular, the rapid development of air-jet looms in the past 10 years has enabled air-jet looms to have many advantages such as high quality, high speed, high output, and high level of self-control, and the range of varieties has greatly increased.

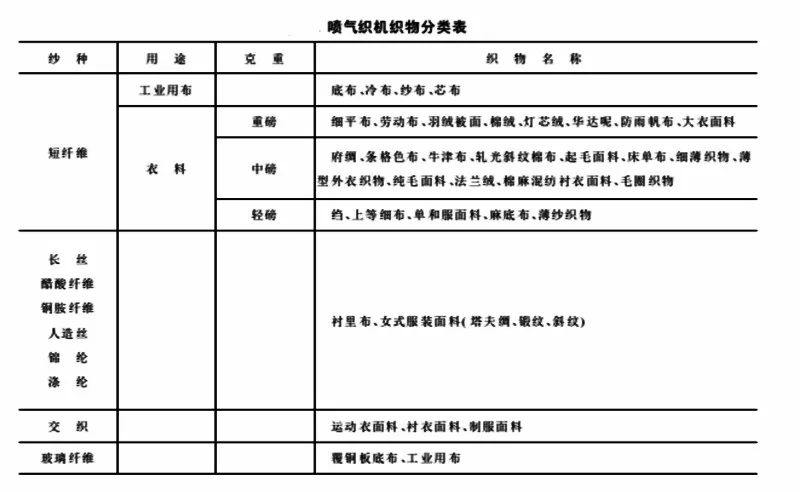

The width of the air-jet loom has risen from 190cm, 280cm to 340cm, 360cm, and 400cm; the main nozzle has been increased from a single nozzle to double nozzles and four nozzles; the multi-color weft insertion system controlled by computer software can carry out 4 colors to 12-color weft selection; the raw material of the weft yarn can be chemical fiber filament, chemical fiber staple fiber, pure cotton yarn, wool yarn, glass fiber yarn, various fancy yarns, etc.; product varieties range from high-density, fine-thin, high-end fabrics to thick and high-density Both thick and thick fabrics can be produced. DORNIER air-jet looms have been used to produce industrial fabrics such as filter fabrics, emery cloth twill fabrics, steaming fabrics and glass fiber wall coverings. The new air-jet looms from Picano from Belgium and Tsudakoma from Japan are also equipped with electronic jacquard, dobby and other shedding systems to adapt to the production of various fabrics.

Rapier Loom

Rapier looms have unique advantages in variety adaptability, but the weft insertion rate is lower than that of air-jet looms, only 1400m/min, which is about 50% of that of air-jet looms; the silk return rate is higher than other shuttleless looms. At present, rapier looms are mainly used for the production of small batches and a variety of weft fabrics such as decorative objects.

Projectile Loom

The projectile loom has advantages in weaving extra-wide fabrics and high-end decorative fabrics, but the weft entry is lower than that of the air-jet loom, 1200m/min; the energy consumption for projectile acceleration only accounts for 15%, and the energy consumption is unreasonable; The material performance of the shuttle torsion shaft and the precision of the weaving mechanism are relatively high; the price is expensive, and the one-time investment cost is large.

Water Jet Loom

Water jet looms have limitations in the quality of weaving, and are only suitable for the weaving of hydrophobic yarns such as synthetic fibers and glass fibers. The relevant components on the loom should be made of stainless steel.

Share to:

Send Inquiry

Mr. Watson Hua

Tel:86-15312570279

Fax:

Mobile Phone:+8615312570279

Email:info@czguanjie.com

Address:88 Changhong Road, Hutang Town, Wujin District, Changzhou City, Changzhou, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.