Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: Xinlong

Brand: FAST

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support, Online Support

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Status: Used

Machine Type: Rapier Loom

Warranty Period: 3 Years

Core Selling Point: High Productivity

Video Factory Inspection: Provided

Core Components: Bearing

Place Of Origin: Italy

Model: Xinlong

Packaging: Box

Transportation: Ocean

Place of Origin: Italy

Port: Shanghai

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CIF

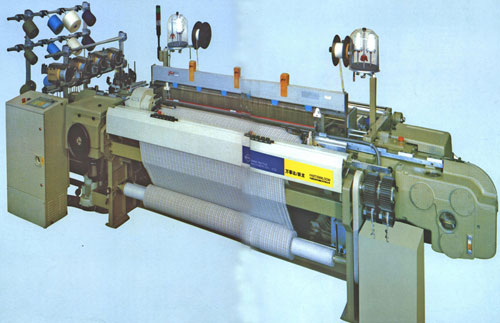

Second-hand Xinlong FAST Rapier Loom

There are many classifications of looms. According to the weaving method, they can be divided into shuttle looms and shuttleless looms. There are also various weft insertion methods for shuttleless looms, such as rapier looms, air jet looms, water jet looms, projectile looms and multi-shed (multiphase) looms.

MasterCard/Xinlong Flexible Rapier Loom is an economical medium and High-Grade Rapier Loom developed by China Textile Machinery Co., Ltd. on the basis of cooperating with Italy NUOVOPIGNONE to produce FAST rapier looms according to the actual needs of domestic users.Our company specializes in selling second-hand rapier looms, with many years of experience, a well-known brand, and quality assurance, Tianzhi is worthy of your trust!

The main technical parameters:

The new dragon rapier loom is a split sley flexible rapier loom. Its mechanical structure is highly accurate, machine adjustment is stable, the operation is reasonable and simple, the maintenance work is small, and it has the characteristics of ergonomics. This new design concept is reflected in the following mechanism characteristics.

1. Opening mechanism

This machine can be equipped with BRG12 treadle device, 2212 type, 2232 type mechanical dobby device, 2660 type, 2650 type electronic dobby device, and mechanical, electronic jacquard device and other opening mechanisms, which can be reversed with the loom through a rigid coupling Box connection can meet the opening requirements of various fabrics.

2. Weft insertion agency

The weft insertion is completed by a four-phase twisted shaft transmission mechanism, a flat four-bar linkage and a fan-shaped tooth reciprocating rotation rapier belt transmission wheel. The mechanism is composed of a number of extremely high-strength, precise-sized components, which maximizes the flexibility of the weft insertion system The characteristic of the rapier head movement is that its acceleration is low, and the running speed curve meets the requirements of no excessive yarn deformation during weft insertion, which is convenient for weft clamping and weft cutting, as well as the transfer of the weft at the center position and the release of the weft. And when changing the width, there is no need to adjust the time when the sword head is transferred in the center again.

The geometric shape and size of the rapier belt drive mechanism provide perfect linear motion, smooth operation, no rapier belt guide, and the technical choice of the shed without rapier belt guide effectively reduces the interference of warp yarns and makes the reed move very smoothly. Reduce the vibration of the machine and lower the noise level.

3. Beat-up mechanism

Beat-up is driven by a conjugate cam, and the sley is driven to swing by a rocking rod fixed on the rocking shaft through the rotor. The system has extremely high torsion strength, enhanced sley swing shaft and strengthened support in the middle of the sley. It provides perfect movement conditions for the reed, sword belt and sword head stroke.

4. Let-off agency

Mechanical let-off device: an active continuous mechanism composed of two parts: Hunt type stepless speed regulation mechanism and warp tension feedback mechanism. The mechanism is simple in structure, convenient to adjust, flexible in rotation, and accurate in feedback. It can make warp from full shaft to empty shaft. The tension difference is only 5%~8%.

Electronic warp let-off device: The electronic warp let-off has high precision in controlling the warp surface tension. In the whole process of weaving, the warp surface tension is strictly controlled, which overcomes the drawbacks of mechanical warp let-off. Electronic let-off has the advantages of simple system structure, wide range of varieties and convenient operation.

5. Take-up mechanism

Mechanical coiling device: This machine adopts continuous coiling. All transmission gears, worm gears, and bevel gears are lubricated in an oil bath in the box. The loom is equipped with 10 changing gears. According to the random supply, there are 269 weft locks. The optional weft density table can choose a set of four changing gears, which can change the weft density within the range of 2~111 pieces/cm (5~282 pieces/inch) to meet the requirements of loom fabrics. Open the weft tight box cover, it is easy to exchange the four shift gears.

Electronic winding device: through the information of the encoder and the let-off sensor on the loom shaft, through the comprehensive coordination of the microcomputer, the stepper motor controls the warp delivery and the fabric roll volume respectively. The synchronization of warp let-off and take-up is better than mechanical take-up.

Take-up roller: The covering material on the surface of the take-up roller, according to the type of fabric, such as general fabrics, silk fabrics, etc., can be equipped with emery, matte rubber, etc. as surface covering materials.

Cloth roll: The maximum winding diameter of the roll is 600mm. The quick release handle allows the machine to change the roll during operation. According to user requirements, an independent large-diameter roll can be installed.

6. Transmission reversing mechanism

The loom is driven by a 5.5Kw AC motor and a high-performance electromagnetic clutch brake. The speed of the loom can be changed by changing the diameter of the motor's V-belt pulley and the adjustment of the gasket between the belt pulley.

The transmission between main drive and reversing, independent selvedge mechanism, from reversing to warp let-off, take-up, weft selection and other mechanisms, adopts high-torque synchronous toothed belt transmission, which is beneficial to the reduction of vibration and noise of the loom , So that the loom works more smoothly.

7. Automatic weft finding system

The microcomputer controls the automatic search for broken weft, and can select a series of phase correction weft broken programs according to the type of fabric to prevent the stop weft block. After the broken weft is found, the reed and the sword head stop at the position of the dead center without affecting the fabric. Therefore, defects in the finished product can be minimized.

8. Auxiliary Organization

General configuration:

--Piezoelectric weft stop device

--Top-mounted temple device

--(Six rows) contact electronic warp stop device

Configure according to user requirements:

--Eight-color or two-color electronic weft selection device

--Suction device

--Selvedge: Leno selvedge device (can be equipped with heald frame belt selvedge device or independent false selvedge selvedge device) or fold-in device (can be equipped with mechanical or electronic side jacquard device) or hot-melt selvedge device

Product detailed introduction: 1. Product purpose and scope of use

The new dragon rapier loom has a wide range of adaptability. It is suitable for the weaving of cotton yarn or synthetic yarn, combed wool yarn and filament. It can weave wool and worsted fabrics, light and medium thick cotton fabrics, twill cotton fabrics and corduroy Fabrics, as well as rayon, synthetic fiber silk, real silk and other fabrics.

Suitable weaving yarn count range: cotton yarn or synthetic yarn 500tex-5tex

Coarse and combed wool yarn 680tex-10tex

Filament 10dtex-1650dtex

Suitable weft density range: 2 ~ 111 threads/cm

Fabric weight range: 40g/m2 ~ 500g/m2

Features of economic rapier loom:

When weaving a strong twist weft fabric, it can inhibit the formation of weft untwisting and weft shrinkage defects; most rapier looms have strong versatility and can adapt to a variety of different raw materials, different thicknesses and different widths. section. The shape of the weft does not need to change the sword head.

Offline and offline dual protection

Offline is online, professional operation team, strong support of online customer service, you can solve your problems at any time.

Full professional service

We adhere to the system of "one-to-one full-process tracking service for customer service", from the moment you place an order to the moment you receive the goods, our professional customer service will provide you with one-to-one service. A whole process tracking service.

Product Categories : Second-hand Rapier Loom

Home > Products > Second-hand Rapier Loom > Second-hand Xinlong FAST Rapier Loom

Send Inquiry

Mr. Watson Hua

Tel:86-15312570279

Fax:

Mobile Phone:+8615312570279

Email:info@czguanjie.com

Address:88 Changhong Road, Hutang Town, Wujin District, Changzhou City, Changzhou, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.